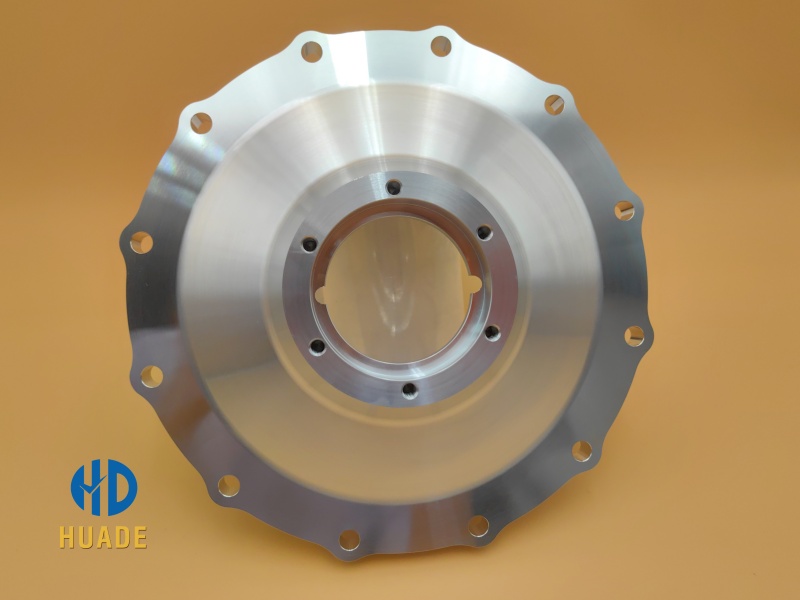

CNC auto parts for off-road engine performance

CNC auto parts play a vital role in improving engine reliability, reducing weight, and extending durability. Off-road vehicles like ATVs often face rough terrain, strong vibrations, and harsh environments.

At شركة دونغقوان هوادي للتصنيع الدقيق, المحدودة, we focus on manufacturing aluminum CNC parts that are engineered for these high-performance conditions.

Why CNC Precision Parts Matter in Off-Road Engines

CNC precision parts do more than hold tight tolerances. They also help engines cool, keep power steady, and stay strong under pressure.

When ATVs face rough roads, poor parts can lead to power loss, heat problems, or engine failure.CNC machining solves these issues by offering repeatable accuracy and stable fitment.

Our 5-axis CNC machining guarantees precision up to ±0.01mm, ensuring parts like engine covers, mounting plates, and housings perform under stress in motorsports and outdoor environments.

Benefits of Aluminum CNC Parts in Automotive Applications

Aluminum is a preferred material for high-performance CNC auto parts. Its unique properties include:

- Lightweight – Reduces total vehicle weight for faster acceleration and improved handling

- Corrosion resistance – Withstands mud, moisture, and chemicals

- Thermal conductivity – Helps dissipate engine heat efficiently

- Machinability – Enables complex designs with fine details

You’ll often see aluminum CNC parts with clean rib structures and symmetrical hole layouts—features only achievable with precision CNC machining.erials.

Common Applications of CNC Auto Parts in ATVs

Our CNC auto parts are commonly used in:

- ATV engine housings

- Gearbox and transmission covers

- Shock absorber connectors

- Brake and suspension mounts

- Customized intake or exhaust flanges

To begin with, each part is built to work well and stay light.

Additionally, we can create custom designs for special or replacement uses.

Why Partner with a Trusted CNC Parts Manufacturer?

Choosing the right CNC precision parts supplier makes a difference. At شركة دونغقوان هوادي للتصنيع الدقيق, المحدودة, we provide:

- Engineering support – Optimize your design for better performance and reduced cost

- Material certification – We use traceable and high-grade aluminum alloys

- Rapid prototyping – Receive CNC samples within 2–3 days

- Small batch flexibility – Low MOQ options available for startups and special builds

We are ISO-certified, and every part goes through strict quality control across design, machining, and inspection stages.grates quality control at every stage—design, programming, machining, and final inspection.

Looking Ahead: CNC Auto Parts in Future Engine Design

As EV and hybrid off-road vehicles grow in popularity, the demand for lightweight CNC auto parts is set to increase.

CNC precision ensures high performance with reduced energy consumption. No matter your goal—building new engines or upgrading existing ones—precision CNC aluminum parts give you an edge.

They keep your designs lighter, faster, and longer-lasting.