CNC auto parts for off-road engine performance

CNC auto parts play a vital role in improving engine reliability, reducing weight, and extending durability. Off-road vehicles like ATVs often face rough terrain, strong vibrations, and harsh outdoor environments. In such conditions, engine components are constantly under mechanical stress.

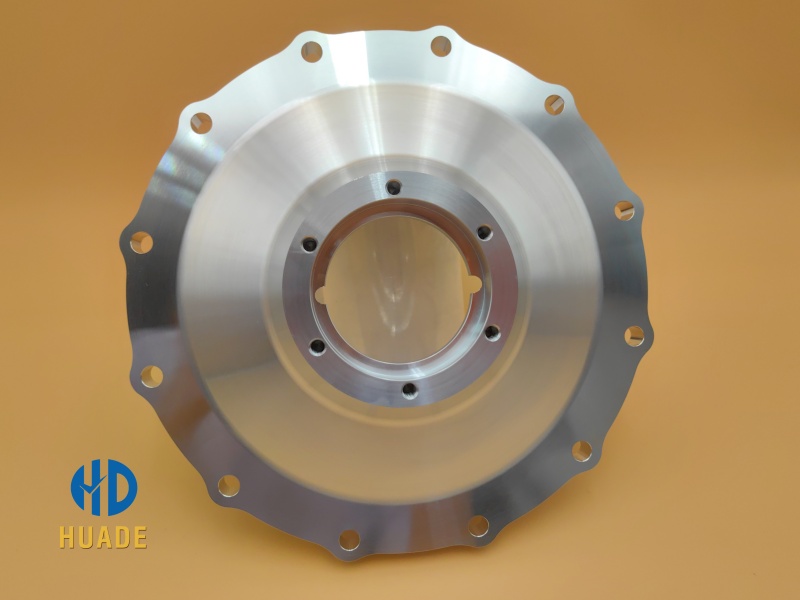

At Dongguan Huade Textize Foreyping Co., LTD, we focus on manufacturing aluminum CNC parts that are engineered for these high-performance conditions. We understand that off-road vehicles demand components that not only fit precisely but also withstand repeated shocks, corrosion, and temperature fluctuations. Every CNC auto part we produce is designed with long-term durability and performance in mind.

Why CNC Precision Parts Matter in Off-Road Engines

CNC precision parts do more than hold tight tolerances. They help engines cool more efficiently, maintain consistent power delivery, and resist deformation under load. Poor-quality parts often result in reduced efficiency, vibration issues, and increased maintenance costs.

When ATVs encounter rough terrain, poorly machined parts may lead to power loss, overheating, or even total engine failure. CNC machining solves these challenges by offering repeatable accuracy, tight dimensional control, and a superior surface finish. These advantages translate directly into better performance and longer part lifespan.

At Huade, our 5-axis CNC machining guarantees tolerances of up to ±0.01mm. This allows us to produce CNC auto parts such as engine covers, mounting brackets, and transmission housings that perform reliably in motorsports, desert races, and utility vehicles operating in tough conditions.

Benefits of Aluminum CNC Parts in Automotive Applications

Aluminum is one of the most commonly used materials for CNC auto parts, especially in high-performance applications. Its unique properties include lightweight, corrosion resistance, high thermal conductivity, and excellent machinability. These advantages make aluminum ideal for off-road environments where strength and weight both matter.

You’ll often find aluminum CNC parts featuring clean rib structures, optimized hole layouts, and reinforced contact surfaces—designs only possible with precision CNC machining. These features help reduce weight without compromising strength and improve vehicle performance and fuel efficiency.

Applications of CNC Auto Parts in Off-Road Vehicles

Our CNC auto parts are commonly used in:

- ATV engine housings

- Gearbox and transmission covers

- Shock absorber connectors

- Suspension and brake brackets

- Custom intake or exhaust flanges

- Electric drivetrain protection covers

These components are built to perform consistently in extreme temperatures, wet or dusty environments, and uneven terrain. We also offer specialized treatments such as anodizing and sandblasting for added surface durability and corrosion resistance.cialized treatments such as anodizing and sandblasting for added surface durability and corrosion resistance.

Why Work with a Trusted CNC Auto Parts Manufacturer?

Choosing a reliable CNC machining partner impacts your bottom line. At Dongguan Huade Precision, we offer:

- Engineering support to optimize your part design for functionality and manufacturability

- Full traceability of materials and compliance with international quality standards

- Rapid prototyping with samples available in 2–3 working days

- Flexible MOQ for low-volume or replacement part orders

We are ISO 9001 certified and maintain strict quality checks at every stage, including 3D measurement, visual inspection, and performance validation.

Looking Ahead: CNC Auto Parts in Future Engine Design

As electric and hybrid off-road vehicles become more common, the need for lightweight, high-strength CNC auto parts is growing. These vehicles rely on efficient heat dissipation, compact design, and precise component fit—all of which are enabled by CNC machining.

Whether you’re upgrading an existing ATV engine or designing a new EV platform, CNC auto parts provide the performance and reliability you need to stay ahead in the market. The ability to customize geometry, apply surface treatments, and scale production quickly makes CNC machining a smart long-term solution.

Learn More About CNC Auto Parts

To explore global tolerance guidelines, you can refer to the official ISO resource:

ISO 2768 standard on CNC machining – https://www.iso.org/standard/60132.html

📩 Contact Us Today

If you’re looking for custom CNC auto parts for your off-road or automotive projects, we’re here to help.

Visit our website: www.hd-ptm.com. Or email: sales@hdproto.com